Get started with energyPRO today and take your energy projects from concept to completion.

Power-to-Methane

From Waste to Value: Optimising Power-to-Methane with energyPRO

What if your biogas plant could do more than just produce biomethane?

What if it could become a cornerstone of a fully integrated, multi-revenue energy system, turning renewable electricity and captured CO2 into high-value fuels while stabilising the grid?

With energyPRO, this is not a futuristic concept; it is a model-driven reality. This use case demonstrates how energyPRO can be used to design, simulate, and optimise a complex Power-to-Methane (PtM) project, showcasing its powerful capabilities for sector coupling and revenue optimisation.

The Promise of Power-to-X

The transition to a decarbonized energy system requires innovative solutions for storing and utilising variable renewable energy sources like wind and solar.

Power-to-X (PtX) technologies, particularly Power-to-Methane, offer a promising pathway by converting surplus electricity into synthetic natural gas (SNG), a versatile and storable energy carrier.

PtM projects face several challenges

High Investment Costs

Volatile Electricity Prices

System Integration

Revenue Stacking

Avoid these risks with energyPRO

Without a comprehensive modelling and optimisation tool, navigating these challenges is a high-risk endeavor. energyPRO provides the necessary platform to de-risk investments and unlock the full economic and environmental potential of Power-to-Methane projects.

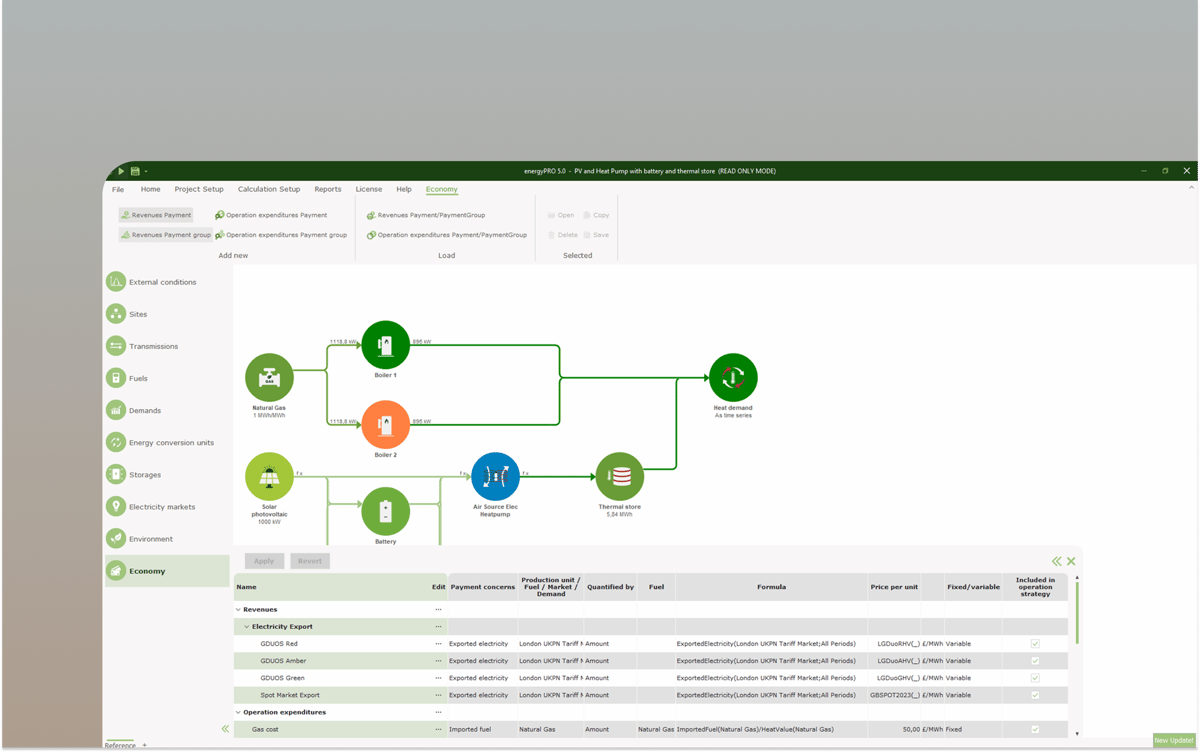

Overview of the system modelled

This use case showcases an advanced Power-to-Methane system modeled in energyPRO. The model integrates several key technologies to create a highly efficient and profitable energy hub:

Renewable Power Generation

A 10 MW wind farm and a 10 MW solar PV installation provide the primary source of electricity.

Power-to-Hydrogen

An electrolyser utilises renewable electricity to produce green hydrogen.

Biogas Upgrading

An amin upgrading unit separates CO2 from raw biogas, producing both biomethane and a pure CO2 stream.

Methanation

A methanation plant synthesises the green hydrogen and captured CO2 to produce synthetic methane (biomethane) and methanol.

Sector Coupling

The system is coupled with a district heating network, utilising waste heat from the electrolyser and a heat pump to meet a 25,000 MWh annual heat demand.

Multi-Revenue Streams

The plant generates revenue from the sale of methanol, biomethane to the natural gas grid, and electricity to the day-ahead market.

Financial and Energy Analysis

The energyPRO model provides a detailed financial and energy analysis of the system over a full year of operation. The results highlight the project’s profitability and efficiency.

The table below summarises the annual financial performance of the plant, based on the energyPRO output.

Financial Performance (Annual)

Energy Conversion Highlights

energyPRO allows for a detailed analysis of each component’s operational performance. The table below shows the utilisation factor for key components, which is crucial for identifying optimisation potential and ensuring the system is dimensioned correctly.

Drive profitability & efficiency - why choose energyPRO?

energyPRO is instrumental in modelling and optimising such a complex, integrated energy system. See how it will add value to your project:

Component-Based Modelling

Easily add, remove, and configure components like electrolysers, heat pumps, and methanation units.

Speed up the prototyping and scenario analysis.

Time-Series Simulation

Accurately model the variable nature of renewable energy, electricity prices, and heat demand.

Get a realistic assessment of your system performance and profitability under real-world conditions.

Economic Optimisation

Determine the optimal operating strategy to maximise revenue from multiple markets.

Ensure that the plant operates at maximum profitability by making intelligent decisions on when to produce, store, or sell energy.

Sector Coupling Analysis

Model the intricate interactions between the electricity, gas, and heat sectors.

Discover new opportunities for profit and sustainability that might otherwise be missed.

Financial Analysis Tools

Access detailed financial reporting, including cash flow analysis, ROI, and payback period.

Make informed investment decisions and secure financing thanks to robust financial projections.

Further extension possibilities

The model presented in this use case can be further extended to explore additional opportunities:

Monetising District Heating

Add a revenue stream for the 25 GWh of heat delivered to the district heating network.

Hydrogen Storage

Incorporate hydrogen storage to provide additional flexibility and grid services.

Ancillary Services

Model the provision of frequency regulation and other grid services to create additional revenue streams.

Carbon Footprint Reporting

Utilise energyPRO’s built-in KPI functions to track and report the project’s carbon footprint.

Integration with other PtX Pathways

Explore the production of other e-fuels, such as ammonia or synthetic liquid fuels.

The modules you need

To model and optimize a Power-to-Methane project of this nature, the following energyPRO modules are recommended:

Recommended package for Power-to-Methane in energyPRO

Learn. Apply. Succeed: Your energyPRO Training Hub

This use case is illustrative, not prescriptive. Proper dimensioning requires hydraulic and biological expertise. Still, it shows how engineers can use energyPRO to simulate dynamic, modular water-energy systems — a vital step toward smart, cost-effective infrastructure.

Dive into our comprehensive courses, webinars, and tutorials to master energyPRO’s powerful features.