Get started with energyPRO today and take your energy projects from concept to completion.

Industrial production in energyPRO

Optimising industrial production with a digital twin for energy

What if your production facility could do more than produce goods?

What if it could operate as an energy-intelligent system, where you can model, simulate, and optimise all energy flows – steam, electricity, heat recovery, cooling – through a single digital representation of your site?

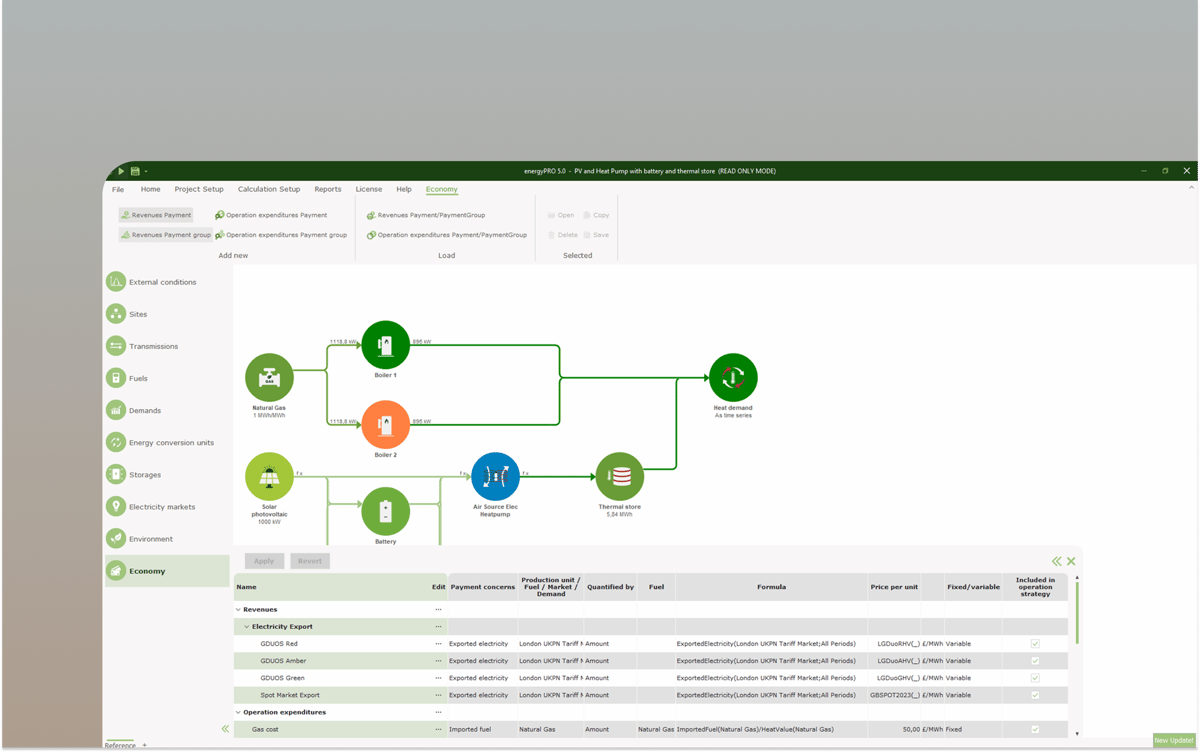

Using energyPRO, industrial plants can develop a full digital twin of their energy and production set-up. This allows you to understand how your energy and production streams interact, identify inefficiencies, and plan operations more effectively.

→ Want a demo?

Want to discuss your needs or request a demo? Fill out the form and we will reach out shortly.

"In relation to industrial processes, energyPRO is particularly applicable and a unique analysis tool, when fluctuating electricity prices, gas prices and energy consumption need to be considered.

With the use of energyPRO, the energy consumption at industrial companies can be modelled, and various scenarios can be simulated to investigate the potential for achieving economic and environmental benefits."

Mathias Terp Munck Specialist Engineer, District Heating

Artelia

Why this matters for industrial production

Industrial facilities typically face several shared challenges

Separate planning

Low system visibility

Energy ignored in shifts

Cost & emission pressure

No visual planning tradition

Face these challenges with energyPRO

energyPRO creates a unified view of your operation and provides the analytical capabilities needed to optimise it.

Overview of the system modelled

In this use case, energyPRO is used to model a large industrial production facility with several energy-relevant components, such as:

- Steam generation and process steam consumption

- Heat recovery systems (e.g., from exhaust gases or condensate)

- Electricity production and consumption from motors, compressors, process equipment

- Cooling and refrigeration systems

- Thermal, gas and fuel storage, where relevant

- Multiple production lines with shift-based demand patterns

The model enables components to be added or adjusted so that different operational or investment strategies can be tested.

Scenario inputs and assumptions

These inputs are used to simulate operational strategies within energyPRO.

Typical inputs may include:

Drive profitability & efficiency - why choose energyPRO?

energyPRO is instrumental in modelling and optimising such a complex, integrated energy system. See how it will add value to your project:

Build a digital twin of all energy-related systems

Get a clear and intuitive overview of energy and production flows.

Make smarter decisions with complete insight into how your systems interact.

Simulate different operational strategies and tariffs

Reduce costs through load shifting and efficiency gains.

Save money and manage unpredictable energy prices with confidence.

Test different production schedules and shift patterns

Improve operational planning and reduce downtime.

Move from reactive to proactive operations for smoother, more efficient production.

Compare CHP, heat pumps, storage, or process changes

Invest wisely and reduce uncertainty around new projects or upgrades.

Test electrification, heat recovery, and low-carbon options

Lower emissions and improve energy efficiency.

Meet sustainability goals and future-proof your operations.

Further extension possibilities

Once the digital twin is established, additional analyses become straightforward:

On-site renewables & storage

Easily add solar, wind, or batteries to your model and see how they impact your energy flows and costs.

Electrify thermal processes

Test how switching to heat pumps or other electric solutions can improve efficiency and sustainability.

Investment scenario comparison

Quickly compare different upgrade options to find the best investment for your site.

Market strategy testing

Simulate how your operations perform under changing electricity prices and market conditions.

Expansion planning

Plan for new production lines or site growth with confidence, using your digital twin.

Emissions & sustainability analysis

Evaluate the environmental impact of your choices and track progress toward sustainability goals.

The modules you need

To model and optimise a project of this nature, the following energyPRO modules are recommended:

Recommended package for Industrial Production in energyPRO

Learn. Apply. Succeed: Your energyPRO Training Hub

This use case is illustrative, not prescriptive. Proper dimensioning requires hydraulic and biological expertise. Still, it shows how engineers can use energyPRO to simulate dynamic, modular production processes – a vital step toward smart, cost-effective infrastructure.

Dive into our comprehensive courses, webinars, and tutorials to master energyPRO’s powerful features.