Get started with energyPRO today and take your energy projects from concept to completion.

Water Treatment

Think water differently: Unlock the hidden energy

What if your wastewater treatment plant could be more than a cost center?

What if it could become an energy hub — treating water, producing biogas, integrating renewables, and adapting to external temperature dynamics?

With energyPRO, this isn’t a distant vision; it’s an actionable reality. This use case illustrates how energyPRO can model and optimise a flexible, modular water treatment system with minimal assumptions and high adaptability.

Design an efficient and economically viable water treatment plant.

.jpg?width=1444&height=1080&name=pictures%20(12).jpg)

Why water-treatment matters

Consider these risks

Energy costs make up 30–50% of the operational expenses in many treatment plants.

Wastewater contains 2–3x more energy than it takes to treat it.

Up to 3% of global electricity is consumed by the water sector – yet less than 10% of WWTPs recover energy.

Biogas recovery from sludge can offset up to 70% of plant energy needs.

Sector coupling with local industry or district heating grids creates circular loops for energy and water reuse.

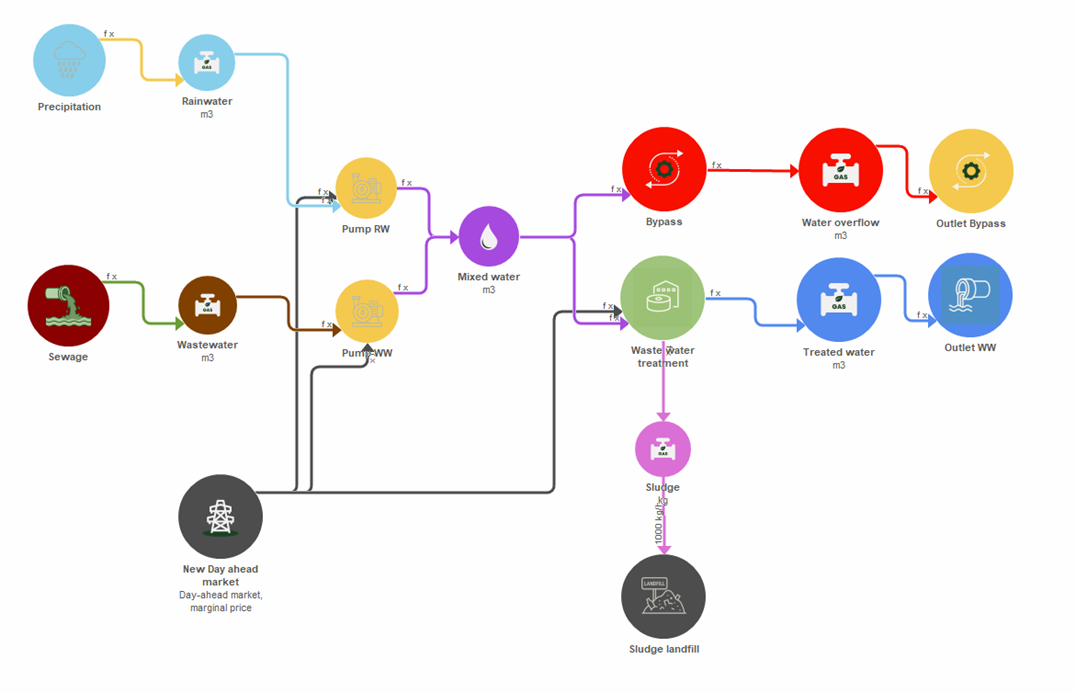

Overview of the system modelled

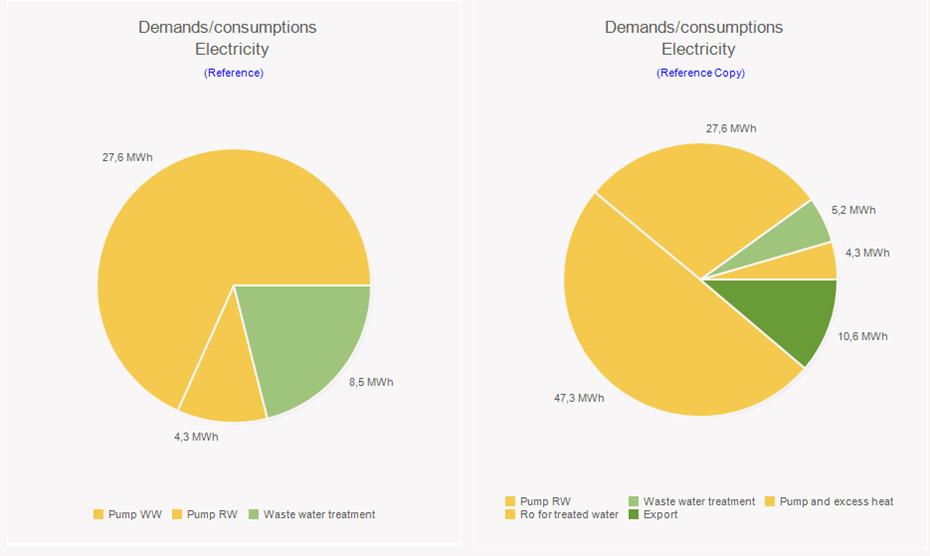

This use case highlights how energyPRO models two distinct wastewater treatment plant (WWTP) configurations — from traditional setups to advanced, energy-integrated systems.

Base model: Traditional WWTP

A simplified model of a conventional plant handling:

- Domestic wastewater inflow

- Rainfall-driven inflow variations

- Basic sludge processing

- Overflow modeling for stormwater capacity checks

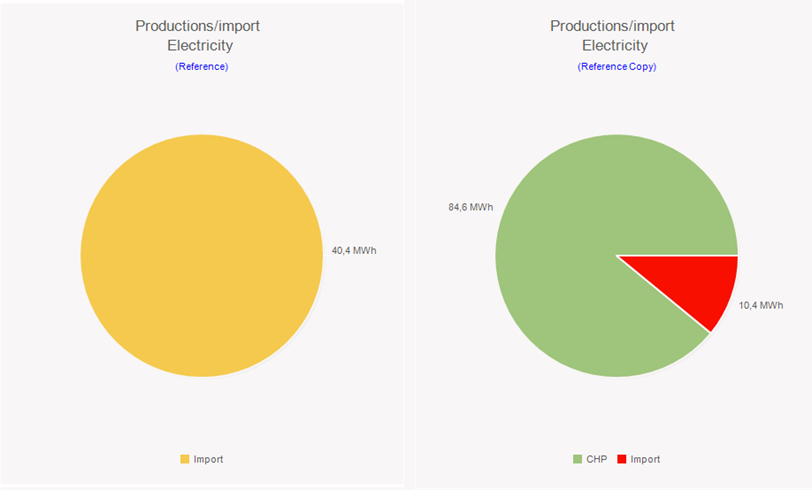

Future-ready model: Energy-optimised WWTP

Building on the base model, this configuration adds:

- Biogas production from sludge digestion

- Wastewater heat recovery

- Overflow modeling under extreme weather conditions

- A Reverse Osmosis (RO) unit serving a nearby industrial facility

- Dynamic biogas reduction during heavy rainfall due to organic load dilution

Both models are climate- and temperature-sensitive, with real-time rainfall inputs — showing how energyPRO enables flexible, adaptive energy planning.

Scenario inputs and assumptions

Modelled components in energyPRO

Wastewater & rainwater inflow

- Influent is divided into a daily domestic base load and a rainfall-driven variable component

- Rainwater acts as a diluent, reducing sludge yield per cubic meter

- Helps simulate storm-driven surges and overflow behavior

Sludge and Biogas Production (Alternative)

- Sludge output is tracked from wastewater processing

- Methane production is temperature-dependent, reflecting seasonal efficiency

- Biogas can be used in a Combined Heat and Power (CHP) module to generate renewable energy

Reverse Osmosis (RO) Unit (Alternative Scenario)

- Sized for an industrial customer’s demand (~30 m³/hr)

- Requires a stable electricity supply, modeled as a fixed load

- Demonstrates integration of WWTPs with industrial water reuse systems

Wastewater Heat Recovery

- Assumes a 5°C temperature drop across treated effluent

- Thermal energy recovered using the formula: Q = m × c × ΔT

- Recovered heat can be reused internally or exported, improving overall plant efficiency

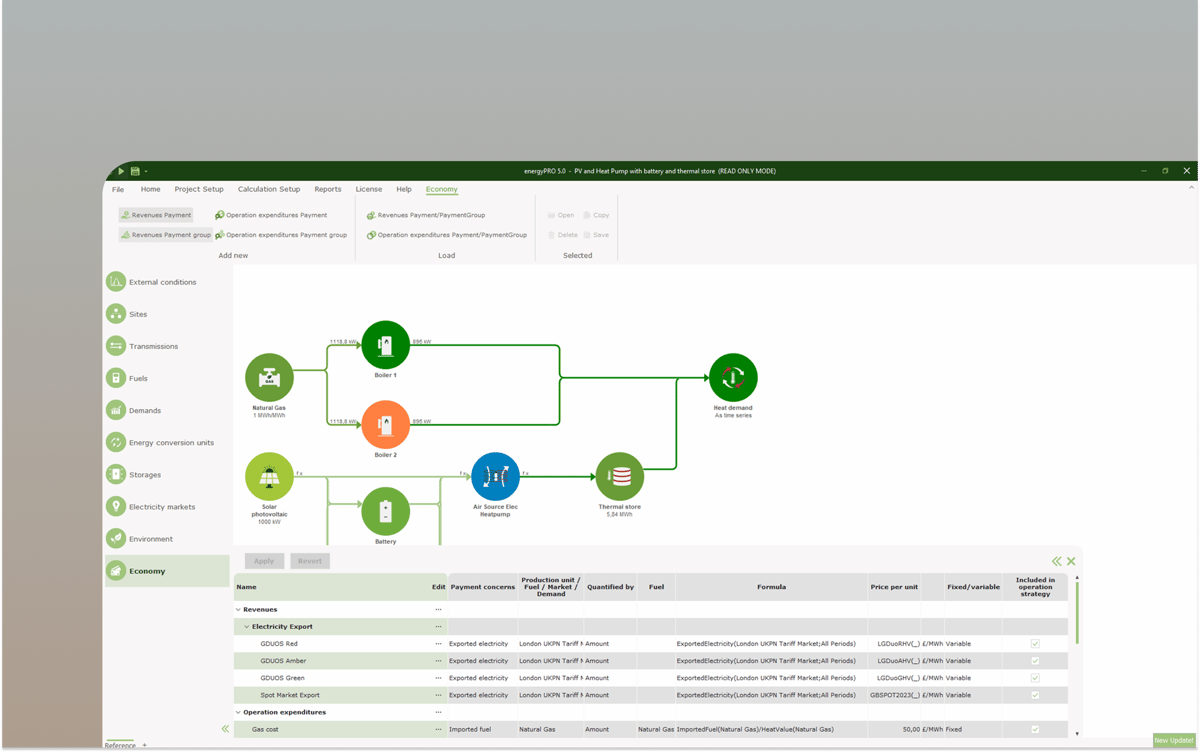

How energyPRO adds value

Further extension possibilities

You can include even more in your project

PV

For lowering electricity cost.

Battery Storage

For smoothing PV power and peak shaving.

Hydrogen Electrolysis

During digestion offload.

Carbon Footprint Reporting

Using built-in KPI functions.

The modules you need

Recommended package for Water Treatment in energyPRO

Learn. Apply. Succeed: Your energyPRO Training Hub

This use case is illustrative, not prescriptive. Proper dimensioning requires hydraulic and biological expertise. Still, it shows how engineers can use energyPRO to simulate dynamic, modular water-energy systems — a vital step toward smart, cost-effective infrastructure.

Dive into our comprehensive courses, webinars, and tutorials to master energyPRO’s powerful features.